November 2025 Scout Motors Production Center Update

Welcome to our monthly progress updates on the construction of our new Scout Motors Production Center. In March 2023, we unveiled our plan for Scout Motors to build our new Scout® vehicles at a state-of-the-art factory to be built in Blythewood, South Carolina. The site, which spans a vast 1,100 acres, is strategically located about 20 minutes north and east of Columbia, South Carolina. This substantial $2–billion investment is set to revolutionize the region, targeted to create over 4,000 permanent jobs. At peak capacity, we plan to produce 200,000 vehicles a year at the Production Center – that’s 40 per hour. We are thrilled to share our progress with you as construction continues.

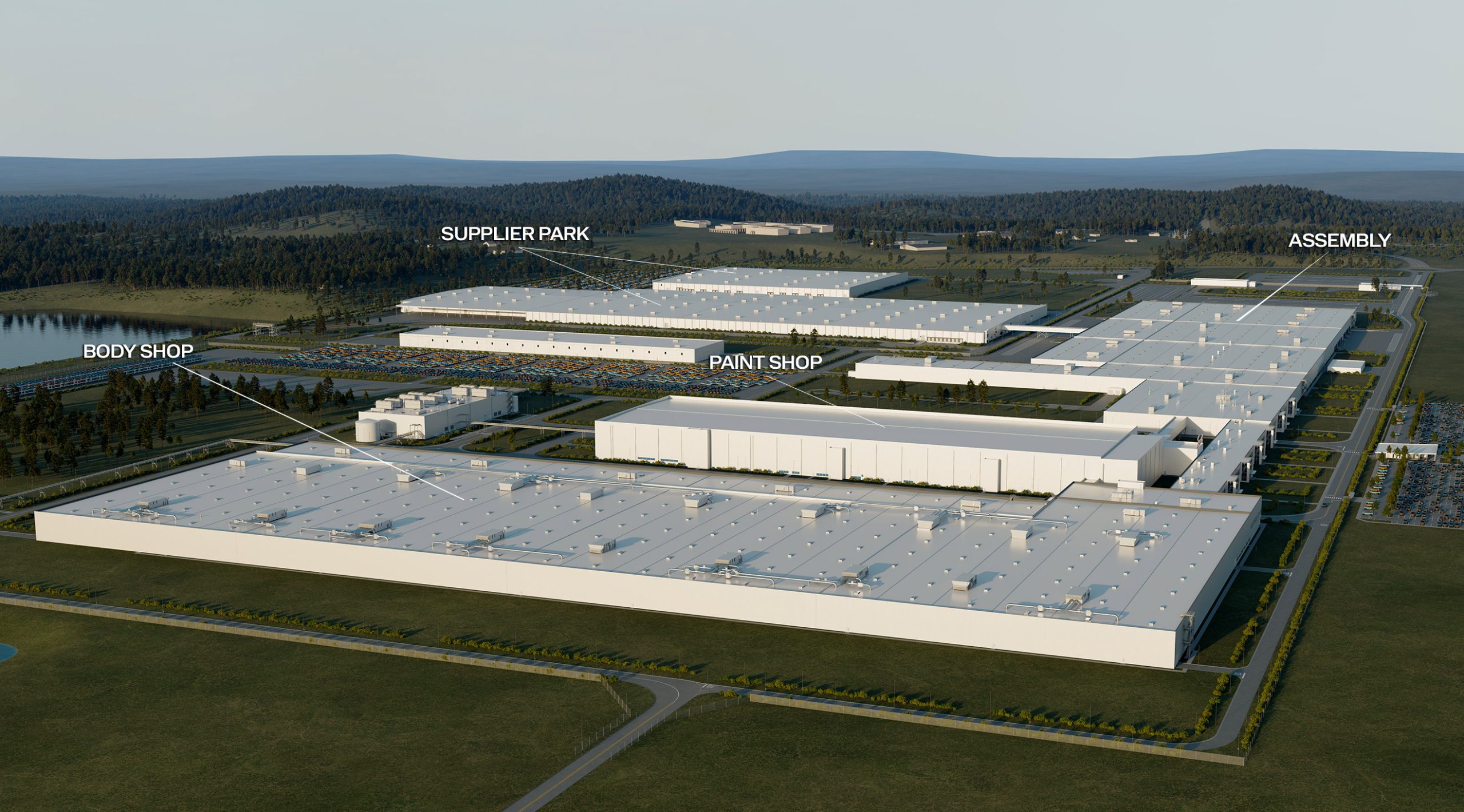

The new Scout vehicles will be built on a newly designed body-on-frame electric vehicle platform. As you can see in the photo above, our Production Center’s main structures include a body shop, a paint shop, and final assembly buildings. The site also features a state-of-the-art training center for our employees and a technology center to support our future vehicles.

In the photo above you can see progress is moving quickly on the Supplier Park buildings.

In September Scout Motors announced an additional investment of $300 million in South Carolina to build a Supplier Park on the site of its Production Center in Blythewood. This initiative, which does not come with any new government incentives, is expected to support approximately 1,000 additional supplier jobs and represents a critical expansion of the company’s existing investment of more than $2 billion in the state.

The Supplier Park will serve as a central logistics and production hub, supporting seamless delivery of parts, batteries, and accessories to Scout Motors’ main assembly operations. The size and scope of the park reflect Scout Motors’ strategy to build a fully integrated, domestic supply chain for its trucks and SUVs.

This close-up of the main assembly building (above) shows that crews have officially enclosed the building, and most work is happening inside, with HVAC equipment being installed and preparations underway for assembly line installation.

When completed, the assembly building will span nearly 1.3 million square feet.

(BELOW) You get a sense of the scale of the assembly building in the photo below. The first assembly line conveyors have started to arrive.

The image above is our first look at the finish area where completed Scout trucks will leave the factory building through the door at the far end of the photo.

The images above and below show a step toward a cleaner future: a large-scale heat pump system arriving at the Scout Production Center, marking the first industrial-scale use of heat pumps in a U.S. automotive plant.

This innovative system will provide efficient heating and cooling for more than 3 million square feet of buildings, replacing traditional gas systems and helping us save the equivalent of 1.2 million trees per year in carbon emissions.