WORDS & PHOTOS: Drew Perlmutter

an Hayes doesn’t really need an introduction. If you’re in the International Harvester® world, you almost certainly know his business—the Binder Boneyard. If you own anything vintage IH, you’ve most likely ordered parts from him before. He has it all; he has everything.

Maybe you even listen to his podcast or subscribe to his YouTube channel of the same name. He’s also a key player in the Scout Motors’ supported Vintage Scout Race Program, lending his expertise as crew chief in the grueling NORRA® Mexican 1000®. Dan’s the guy you call when you’re in trouble—and the reason so many Scout trucks are still out there kicking up dust today.

The physical Binder Boneyard is located in central Oregon, about an hour north of Bend. It’s situated in a valley between the Deschutes River and overlooks the Crooked River—the view could be a postcard. “Packing” was on the punch list today at the shop. Dan and his partner, Josie, were loading up for “Nationals.” Each year, they make the nearly 2,500-mile trek across the states in support of the 34th Annual IH® Scout® and All Truck National meetup in Springfield, Ohio. The two of them were packing up body panels, transmissions, engines, driveshafts—parts for sale and parts already sold to be delivered along the way.

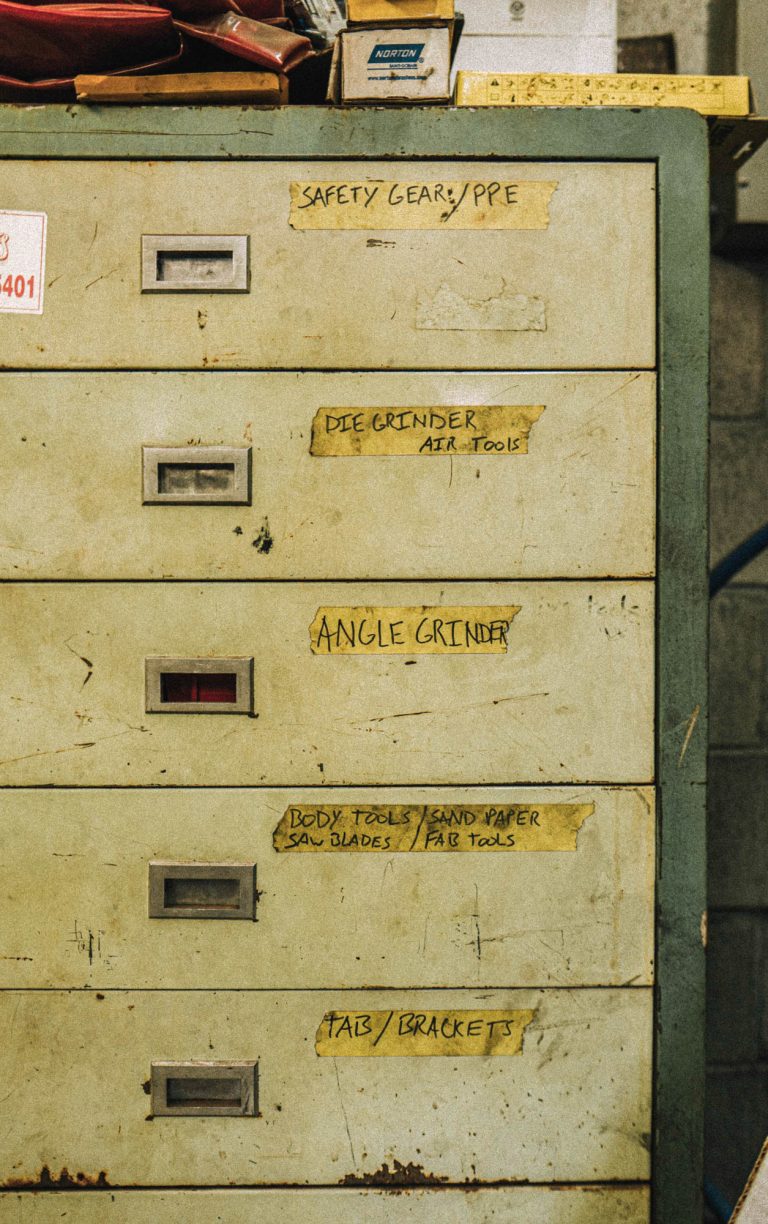

“You know, I hate when people call it a junkyard,” Dan says. “But I know what it looks like,” he laughs. But don’t call it a junkyard. It’s not—it’s far from it. It’s a goldmine, a treasure trove. If you need a part, it’s here. If it’s rare or hard to find, it’s probably here. And Dan knows exactly where it is. “My scrap bin only gets emptied once a year. I don’t throw stuff away. Everything gets reused or sold.”

From the road, the yard is unassuming. But upon entering, you are greeted by an impressive and extensive collection. International Harvester vehicles of every make and model from every decade expand in every direction. Tractors, Travelall™ vehicles, cabovers, Cub Cadet™ outdoor power equipment, Scout models, and more. As you walk the yard, the beauty in the chaos becomes apparent. The organization reveals itself, patterns arise, and you can find your way.

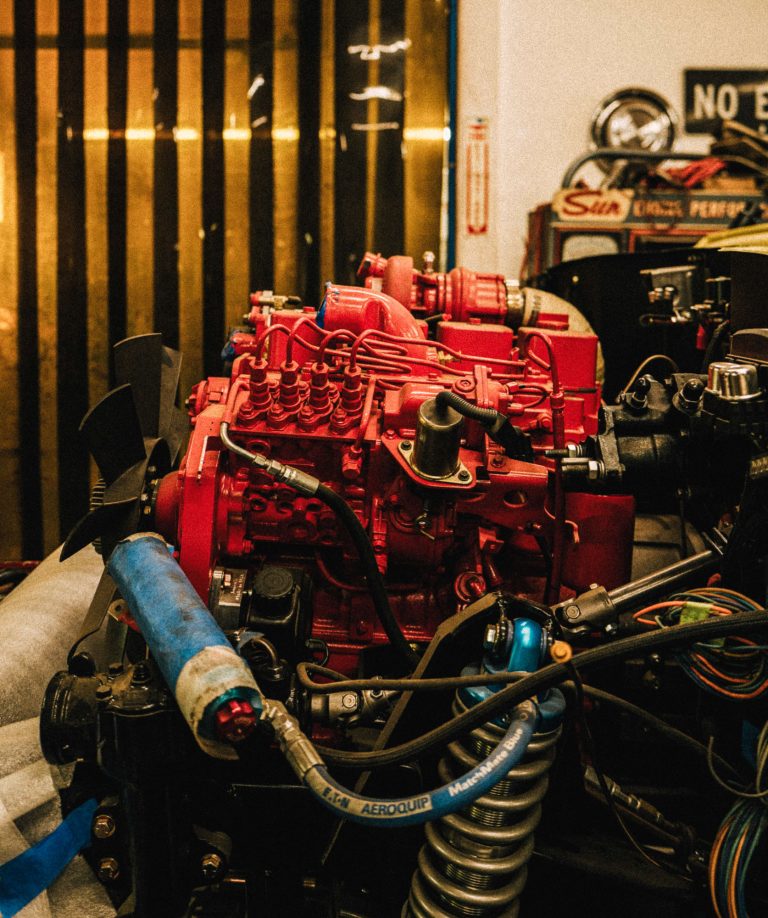

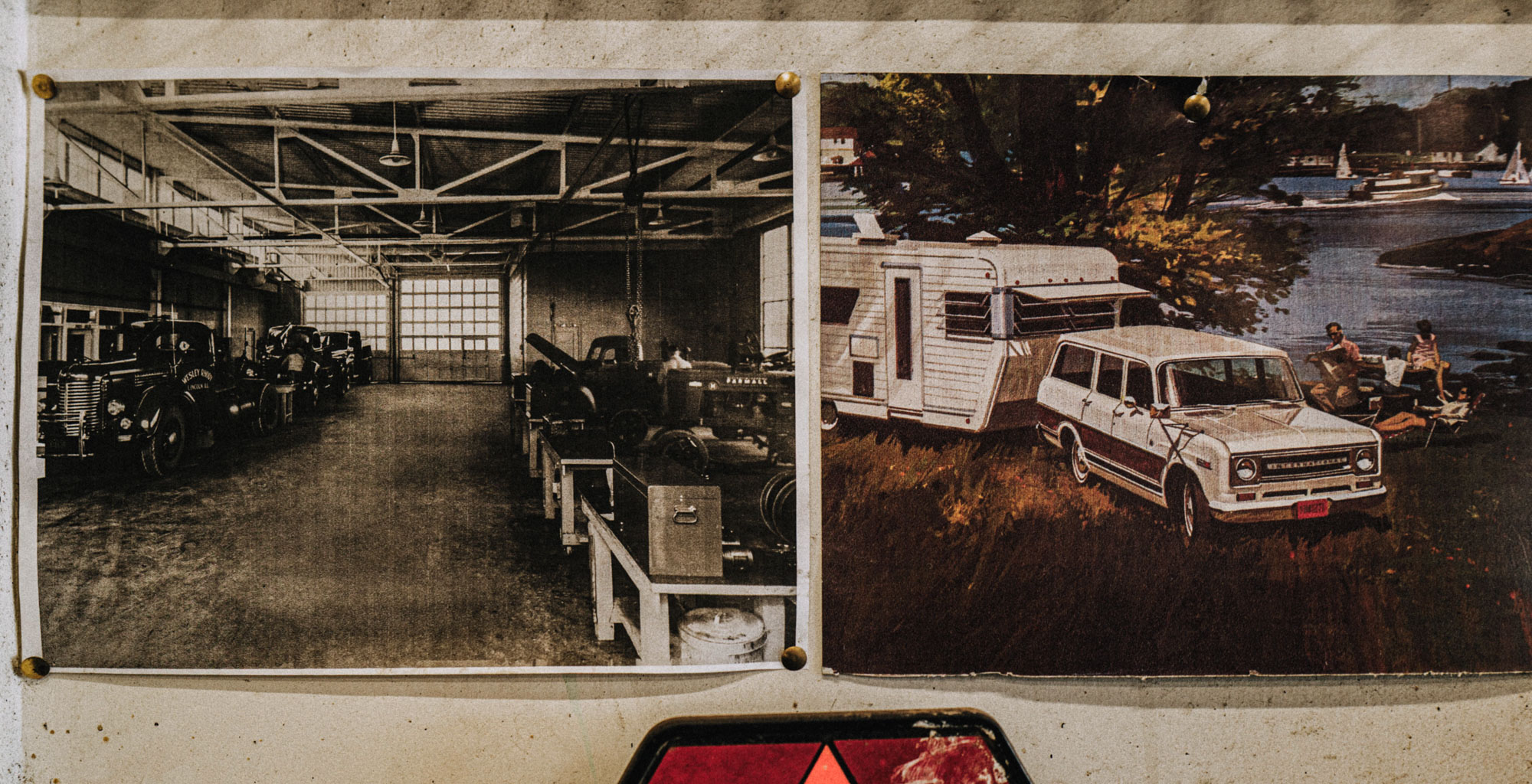

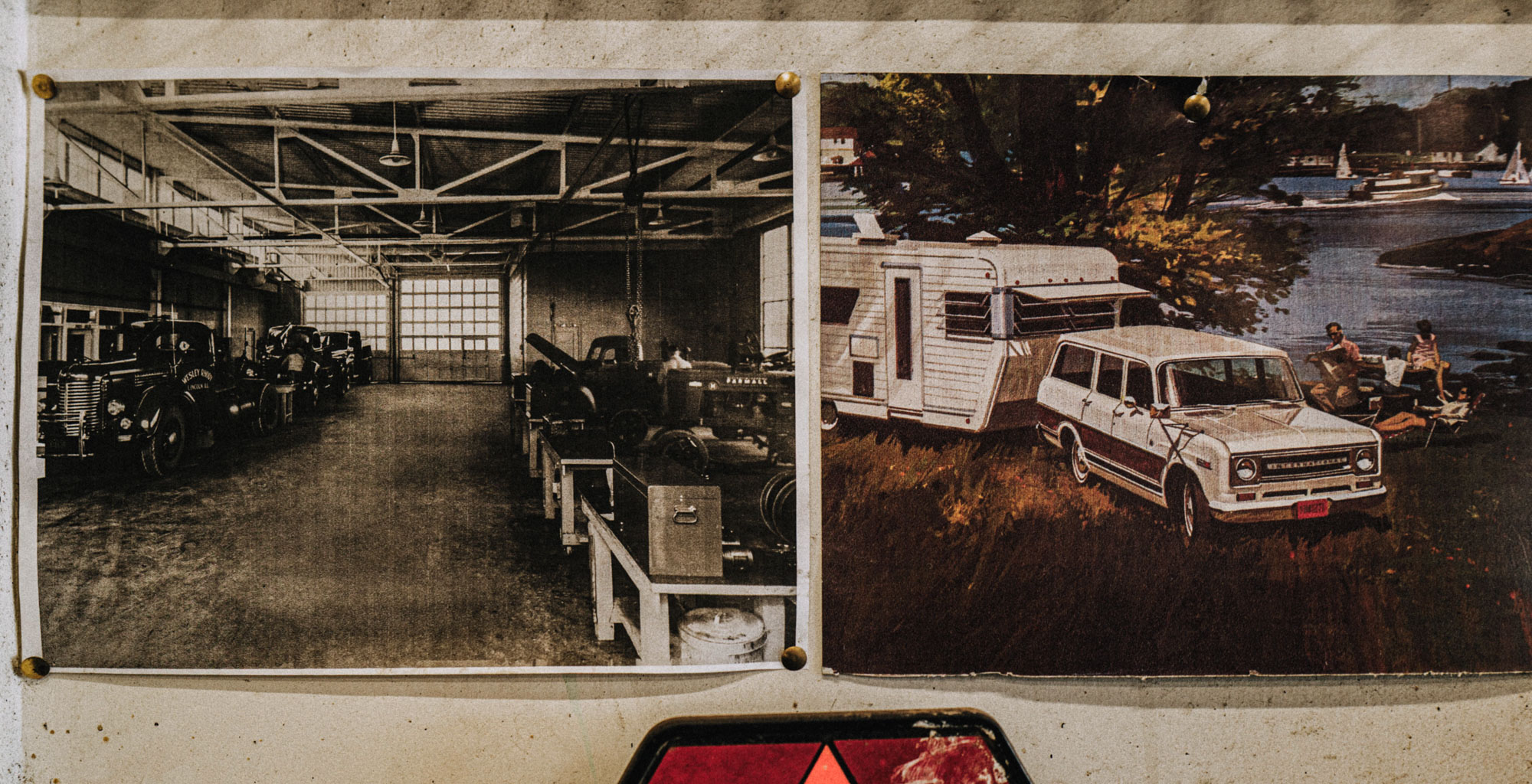

And at the heart of it all is his shop. The large garage door transports you to another world—from the parts yard into the service center. A cliché garage in all the best ways. Memorabilia hangs on every wall, along with old hand-lettered signs and vintage posters. IH advertisements from the 1950s and ’60s are framed above desks. Engines, transfer cases, and differentials cover workbenches, all in various states of repair. Wiring looms slither across frames and under dashboards. A few customer projects were in the queue, mostly beneath plastic to avoid any harm.

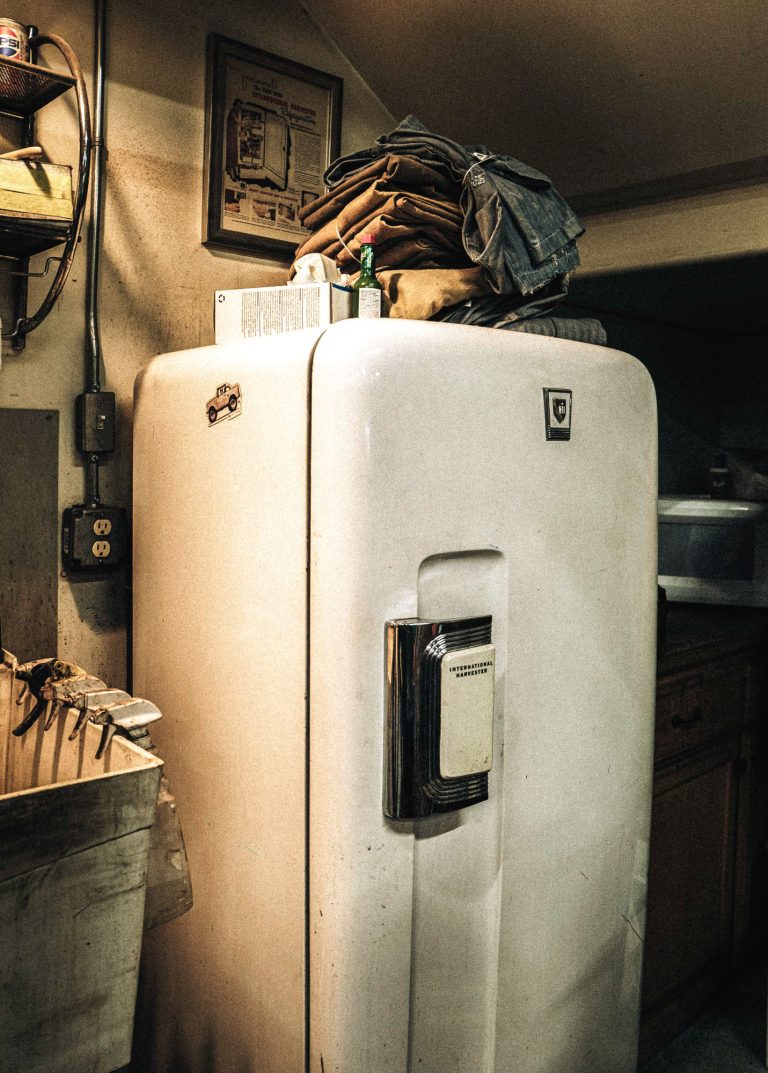

Dan quickly runs through a status report on all the current jobs. The list goes on and on. Stopping near some heavy tooling, Dan proudly shows off his 1941 South Bend lathe, originally from a local high school. Vintage American machinery fixing vintage American vehicles—what more could you ask for? Dan points out another one of his prized possessions: a 1950s International Harvester refrigerator, with the original ad framed above it. Fully functioning and ice cold.

In the welding shop, a truck body sits on stands, waiting for sheet metal repairs. Being here, you’d think Dan had been doing this his whole life—growing up around Scout trucks or being a professionally trained mechanic. But that’s not the case at all. He grew up a hog farmer, whose family replaced more equipment than they fixed, so wrenching was never a thing. After college and working various jobs, Dan found himself in need of a vehicle. He wanted something four-wheel drive so he could hang in the snow with his buddies, but it had to be cheap. They all had Jeep®, Blazer™, and Bronco®, models which were a bit rich for his taste—even 20 years ago. And that’s when he found a Scout truck for $800. It ran. It drove. It changed his life.

It was far from perfect, though. “I had no mechanical skills. I bought it and immediately thought—well, I better figure out how to fix this.” Armed with a shop manual and a Petersen’s 4-Wheel & Off-Road subscription, he started wrenching out of necessity. This was before the internet too, so Dan learned a lot the hard way. And he was hooked. “I ruined a lot of stuff,” he laughed. “But it was okay, because back then everything was cheap. I was getting these Scout trucks for almost nothing and figuring out how to take them apart and put them back together.”

One truck led to another. Soon he was spotting them in fields, knocking on doors, and making trades. “One lady literally tried to give me her husband’s Scout truck just to get it out of the yard.” Time passed, the repairs got better, the builds more ambitious. And his yard got crowded.

“I did what they tell you not to do—I turned my hobby into a job.” That’s the contradiction at the heart of Binder Boneyard: Hayes’s labor-of-love-turned-livelihood. It’s not glamorous. It’s not easy. And in the increasingly rarefied air of vintage 4×4 restorations, it’s rare to find someone as deeply embedded as Hayes. He’s been immersed in International Harvester trucks for over 25 years. He knows every nut, bolt, and bracket better than anything. And more than that, he knows what they mean to people.

Within the last decade of his work, social media began to change everything. Just from sharing his own work and trucks, he gained a following. Getting behind the camera and sharing a behind-the-scenes look into builds—even repair videos—folks started reaching out to him, asking for help with their vehicles. Dan now had a solid reputation. “What people really know about me and the shop is that we drive Internationals every day. We’re real-world users.”

Dan fell into the world of customer builds almost by accident, taking on project after project and eventually opening up a dedicated shop. Customer jobs started lining up, and he got busy. Clients often want the impossible: “40-inch tires, no lift, plush ride quality, and something they can daily drive. You have to keep them realistic and direct their build,” Dan says. He became more selective over time, steering projects toward practicality while maintaining the heritage and integrity of these vehicles.

Every restoration left behind donor vehicles, and the surplus grew. Soon, parts became the business. A turning point came when Dan realized the leftovers from projects were more valuable than the jobs themselves. “We’d end up with two or three parts trucks, and I couldn’t keep them all. So I started parting them out. And pretty soon, we were making decent money just selling parts.” And it just kept going. The vintage IH community continued to grow over the years. It was folks like Dan who kept the scene alive, offering a source of parts and a wealth of knowledge. Used parts were doing more than just keeping the lights on—sometimes even funding payroll in slow months. From there, Dan made the strategic pivot. Now, Binder Boneyard is one of the largest used IH parts operations in the country, shipping rare and hard-to-find components across the U.S.

Part of Dan’s success is the fact that he cares—he has a passion for what he does. Along the way, he had influential figures in his life who taught him valuable things. Whether intentionally or not, Dan is on a mission to preserve and pass on what was handed down to him, keeping the legacy of the brand alive. He just likes to impress the old guys, but also, he wants to inspire the next generation. His media channels are a great resource for nearly everything IH- and Scout-related. These machines continue to outlive us, so this is the writing on the walls. “It’s my duty to carry on these memories, their legacies, and this knowledge base. People took the time to teach me. Now I’ve got to do the same.”

Dan and Josie run the day-to-day operations—driving vintage Scout trucks daily, answering phones, pulling parts, and keeping a finger on the pulse of the IH world. If they’re not driving across America to sponsor an event, they’re probably fulfilling your order. The Binder Boneyard is full-up now. The yard is out of space, and customer projects fill the calendar for the next two to five years.

Dan has high hopes for the future, with dreams of expanding storage for his collection and streamlining the inventory. The ultimate goal is keeping these machines alive—one of his biggest contributions being the continued sourcing and cataloguing of parts, all from his front yard.

“One day,” he says, “when I’m ready to retire, I can sell the whole thing. Ten shipping containers, all labeled and ready to go.”